GVS L-shaped vice machine vice

Prices incl. VAT plus shipping costs

Ready to ship today,

Delivery time appr. 1-3 workdays

- Order number: gvs-lss

Advantages

- Worldwide shipping

- Own production and development

- By bikers - For bikers

GVS L-shaped vice machine vice

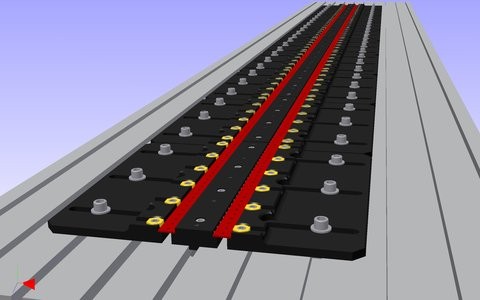

Are you still clamping, or are you already milling? L-shaped vice S - clamping technology V - moving

For one metre, you need: Vice

• 5 pieces, approx. 160 mm jaw width • Price: approx. £3,000.00, total price: £15,000.00

• Weight: approx. 40 kg, total weight: 200 kg

• Alignment 30 - 40 min. The assembly work involved in setting up the machine vice is very unpleasant for the machinist and leads to downtime on the machine.

In comparison, our bar and plate vices: Bar vice

• 2x 500 mm • Price approx. £885.00, total price: £1,770.00

The machine vice is the basic tool for clamping milled parts securely and accurately. However, anything longer than the width of the vice leads to clamping problems. This problem can be solved by setting up several vices next to each other. For example, for a length of 1 metre, this results in 5 vices at 160 mm, with each vice weighing approx. 60 kg.

Aligning the vices can take about 45 minutes. The price of a vice is around £1,750, which means that five vices cost £8,750. The assembly work is very unpleasant for the machinist and leads to downtime on the machine. As of today, there is not only the machine vice clamping system, but also the LSV clamping system for longer and larger parts. This eliminates almost all improvisation and solves questions such as ‘How do I clamp something?’ all by itself.

This ensures enormous throughput times for CNC milling machines.

With the LSV, you can clamp elongated and square parts of endless length with high precision and very quickly.

We estimate the set-up time for one metre to be 5 minutes.

Depending on the table size, several workpieces can even be clamped one after the other, which significantly increases the throughput time. The LSV consists of a fixed beam and a floating beam, which are available in lengths of 55 mm, 250 mm and 500 mm. Other lengths can be manufactured according to customer requirements.

Six clamping elements are embedded in the floating beams. These exert a clamping pressure of well over 1000 kg each.

In addition, a 6H7 index hole is incorporated into each mounting edge of the beam every 20 mm for attaching the workpiece. The fixed beam is tempered to 50 HRC, making it possible to level the beam with high precision to 0.01 at any time. These components can be used to assemble the required length in a rail-like manner to suit the workpiece.

If desired, the end faces to be cut can also be left exposed. There are no limitations to the mobility for fixing workpieces, as the chip groove for M16 is 135 mm long. The movable beam can not only be aligned parallel, but also wedge-shaped, thus clamping a combustion part.

Another modern and highly productive feature is the ability to machine complex milling and drilling workpieces side by side from a single strip. This leads to enormous unmanned throughput times. The workpieces are sawn from below and from both sides, leaving approx. 1 mm in the middle. This is then broken off by hand.

Item number:

LSV 55 for the 55 mm bar vice

LSV 250 for the 250 mm bar vice

LSV500 for the 500 mm bar vice

| Product type: | Werkzeuge |

MV Motorrad Technik GmbH

MV Flexible adjustable Rider's Footrest

MV Motorrad Technik GmbH

MV Flexible adjustable Rider's Footrest

GVS Spanntechnik

Stop for vice GVS, magnetic stop, with one or...

GVS Spanntechnik

Stop for vice GVS, magnetic stop, with one or...

MV Motorrad Technik GmbH

MV Lowered / Adjustable Passenger for Honda XL...

MV Motorrad Technik GmbH

MV Lowered / Adjustable Passenger for Honda XL...

MV Motorrad Technik GmbH

MV Manually Adjustable Handlebar K1200RS...

MV Motorrad Technik GmbH

MV Manually Adjustable Handlebar K1200RS...

MV Motorrad Technik GmbH

MV's Handlebar GPS and Device Holder with 25 mm...

MV Motorrad Technik GmbH

MV's Handlebar GPS and Device Holder with 25 mm...

MV Motorrad Technik GmbH

MV Vario handlebars, manually adjustable...

MV Motorrad Technik GmbH

MV Vario handlebars, manually adjustable...

MV Motorrad Technik GmbH

MV Lowered / Adjustable Rider Footrest for...

MV Motorrad Technik GmbH

MV Lowered / Adjustable Rider Footrest for...

MV Motorrad Technik GmbH

MV Device Adapter for GPS Mounted on Brake or...

MV Motorrad Technik GmbH

MV Device Adapter for GPS Mounted on Brake or...

MV Motorrad Technik GmbH

MV replacement footrest - suitable for any bike

MV Motorrad Technik GmbH

MV replacement footrest - suitable for any bike

MV Motorrad Technik GmbH

MV Lowered Driver Footrests BMW K1200RS 1997-2001

MV Motorrad Technik GmbH

MV Lowered Driver Footrests BMW K1200RS 1997-2001

MV Motorrad Technik GmbH

MV Electric Adjustable Handlebar BMW K1200RS

MV Motorrad Technik GmbH

MV Electric Adjustable Handlebar BMW K1200RS