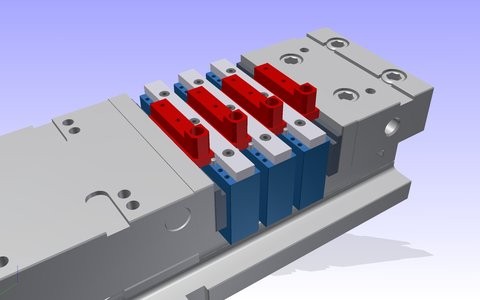

GVS Floating Vise Jaw

The latest innovation in the multiple clamping sector in an existing Hilma machine vice, for 125 and 160 vices. This means: rapid availability and use of the GVS jaw.

Example: five GVS jaws can be inserted with the desired zero-point fixing in approx. 30 seconds.

The base body is made of hard-anodised (60) aluminium, giving it a homogeneous weight and sliding properties.

The clamping strip, equipped with zero-point holes, is made of high-quality, surface-hardened steel. It is screwed in place with two screws and aligned with two dowel pins. This means that it can be replaced in no time at all after damage.

With the GVS clamping jaw, you can optimise your Hilma vice and gradually expand it after each multiple clamping. The main advantage of these jaws is that the width of the jaw allows each workpiece to be machined individually all around. This redesign in the clamping technology of milled parts eliminates the need for fixtures and expensive multiple clamping systems. This results in high unmanned throughput times. The GVS jaw makes this possible.

The time saved allows the operator to deburr or write a new programme, for example, or to prepare for the next job. Owners of vices from other manufacturers with flat bed guides can also be served; please enquire.

| Product type: | Clamping technology, Werkzeuge |

MV Motorrad Technik GmbH

MV footrest lowering BMW R1300GS for the...

MV Motorrad Technik GmbH

MV footrest lowering BMW R1300GS for the...

MV Motorrad Technik GmbH

MV Flexible adjustable Rider's Footrest

MV Motorrad Technik GmbH

MV Flexible adjustable Rider's Footrest

GVS Spanntechnik

GVS Hollow Spindle Stop Lathe Chuck Stop Chuck...

GVS Spanntechnik

GVS Hollow Spindle Stop Lathe Chuck Stop Chuck...

MV Motorrad Technik GmbH

MV's Handlebar GPS and Device Holder with 25 mm...

MV Motorrad Technik GmbH

MV's Handlebar GPS and Device Holder with 25 mm...